Both the UK and China have committed to lowering carbon emissions and reducing the impact of the manufacturing sector on the environment. So what scope is there for cooperation between the UK and China in green manufacturing?

China and the UK are the largest and ninth-largest manufacturing countries in the world respectively. Despite both countries having made great efforts in developing the green manufacturing sector, there remains a lot of potential for joint projects and initiatives.

A new report produced by CBBC, the Department for International Trade (DIT) of the UK government, and the Centre for International Economic and Technological Cooperation of the Ministry of Industry and Information Technology of China (CIETC-MIIT) aims to explore the scope, attributes, and strengths of green manufacturing in both countries, identify opportunities, and make recommendations for governments, industries and researchers in order to boost trade, investment, and international cooperation between China and the UK. (Click the link at the bottom of this article for the full report).

First off, what exactly is green manufacturing?

There are a number of attributes that can be used to characterise or define green manufacturing:

- Green manufacturing companies embrace the challenge of de-carbonising at scale and are committed to a net zero or carbon neutral pathway and target.

- Green manufactured products deliver economic, social and environmental benefits.

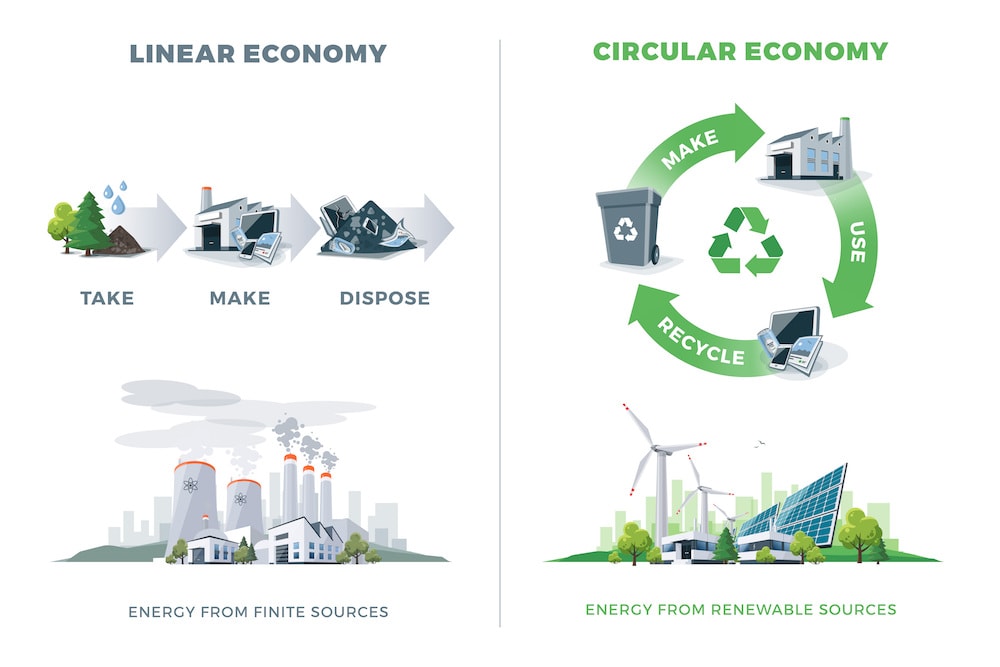

- Green manufacturing companies embrace the circular economy and other strategies to maximising value from resources.

- Green manufacturing companies and products do not have adverse effects on biodiversity or human health and wellbeing.

- Green manufacturing companies seek external independent validation of their progress through certification of their plants and operations, their energy, carbon, and resource footprint, or their labelling of products.

The UK is at the forefront of creating the standards and certifications that are used by green manufacturing companies. For example, the world’s first product carbon footprint standard, PAS 2050, was developed by the British Standards Institute.

Comparing a circular economic model and a linear economic model

Green manufacturing in the UK

Green manufacturing in the UK is not just about the goods it makes or the way in which they are produced, but also about the people that make them and the spaces, regions, and ecosystems in which they are made. The UK manufacturing industry excels in areas such as clean technologies, energy efficiency, eco-design, and new and sustainable business models, and the UK government has made great efforts to support green manufacturing geared towards a circular economy.

According to a 2016 UK parliamentary report, a more circular UK economy could be worth £9-29 billion a year and would create 10,000-175,000 jobs across different skill levels by 2030. At the same time, a survey conducted by the Office for National Statistics revealed that the low carbon manufacturing industry was estimated to be worth £15 billion and employed a total of 83,600 people in 2018.

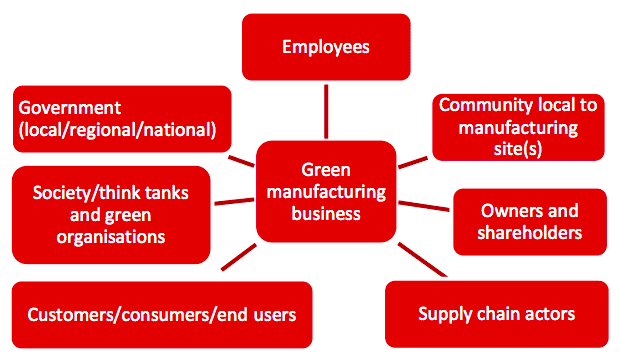

Who are the main stakeholders in green manufacturing?

Case Study: A car manufacturing start-up for hydrogen-powered fuel cell electric vehicles

Riversimple is a UK car manufacturing start-up for hydrogen-powered fuel cell electric vehicles founded by former motorsport engineer and racing driver Hugo Spowers. The company is not only developing revolutionary technologies for next-generation cars, which are lightweight, fast, and sustainable, it also follows a unique value proposal focused on the “systematic elimination of the environmental impact of personal transport.”

Technological innovation is not sufficient to achieve sustainability. It requires a system change and innovations in business models to make sectors such as car manufacturing more sustainable. Riversimple puts a substantial amount of effort into developing sustainable business models. It is a car company, but it does not sell cars; instead of selling cars, the company sells mobility as a service (e.g., the use of cars and customer use of mileage).

I am pleased to see the UK and Chinese governments, academics, industrial associations and businesses working together to deepen international cooperation and boost bilateral trade and investment. I hope the cooperation mechanisms and case studies shared in this report will accelerate the future development of the green manufacturing industry and intensify international cooperation.

– John Edwards, Her Majesty’s Trade Commissioner for China, Department for International Trade

In the Riversimple model, car users are charged for miles travelled plus a monthly fee, or are given a fixed price three-year leasing fee covering all services, such as maintenance, road tax, insurance and, importantly, fuel. Retaining the ownership of the cars, the company has more incentive to design a car that lasts longer and can be more easily reused, re-manufactured and recycled.

Green manufacturing in China

China became the world’s biggest manufacturing economy in 2010 when it surpassed the manufacturing output of the US. Today, China is the only nation that meets all the industrial categories in the United Nation’s International Standard Industrial Classification for All Economic Activities (ISIC). Although its manufacturing industry generates great wealth, it also leads to substantial ecological and environmental problems with an ever-expanding demand for energy and resources and increasing emissions.

Nevertheless, green manufacturing is being applied as a modern manufacturing model that considers the environmental impact and resource benefits. The Ministry of Industry and Information Technology (MIIT) — specifically, the Department of Energy Conservation and Comprehensive Utilisation — takes the lead in green manufacturing in China.

In 2015, with the implementation of the Manufacturing Power Strategy, green industrial development was promoted to new heights, and green manufacturing was regarded as one of the five key national projects. The Environmental Protection Law, the Law of Prevention and Control of Water Pollution, and other important laws have been revised, and the legal protection system has been improved greatly. Policies implemented include the Manufacturing Power Strategy and the Plan of Green Industrial Development (2016–2020), and the Guide for Green Manufacturing Engineering Implementation (2016-2020).