In the seventh of our series on COP26, we look at what kinds of e-mobility and green transport solutions companies in the UK and China are developing, and what needs to change on the practical and policy levels to help these solutions go even further

Transport accounts for around a quarter of carbon emissions from the combustion of fossil fuels. In China, the number is around 10%. These emissions will have to be significantly reduced if the world is to achieve net zero in this area, but transport energy demand is growing – extrapolating from recent trends, analysis by BP suggests that the number of cars on the world’s roads could double from one to two billion in the next two decades.

Reducing emissions from transport will require action to decarbonise the internal combustion engine of cars as well as deploying battery electric vehicles. BP’s 2020 Energy Outlook suggests that by 2050, electric vehicles will account for between 80-85% of the stock of passenger cars in a Rapid Transition scenario and Net Zero scenario, and 35% in a Business-as-Usual (BAU) scenario.

Furthermore, electrification may not be commercially or technically feasible in other parts of the transport sector, such as long-distance haulage, shipping or aviation, or in certain geographies. A range of technologies, including biofuels, ‘e-fuels’ and hydrogen, may be required as well as making use of developments in the broader mobility revolution such as autonomous vehicles and shared mobility services.

What policy support is required?

Sophisticated policy changes may be needed to tackle this complex challenge at a systems level.

Gasoline and diesel phase-out

Phasing out sales of new gasoline and diesel cars is one way to help decarbonise road transport. Enable and Accelerating such a phase-out – and making it successful – will require the development of alternative low carbon behaviours, technologies, fuels, markets and infrastructure, including modal shift; vehicle efficiency; improved battery and fuel cell technology; ultra-fast charging technology; greening of the grid; and hydrogen/associated infrastructure.

Vehicle efficiency

Vehicle efficiency improvements can reduce oil use in passenger cars (and hence carbon emissions) by roughly twice as much as electrification. Therefore, it is important to identify cleaner and better fuels and lubricants, and increase the use of alternative fuels and ‘drop-in’ biofuels – those compatible with existing infrastructure and vehicles.

Access to ultra-fast charging

Easy access to ultra-fast charging (>150kW) will help address concerns over range, and provide a solution for those that cannot charge at home, enabling the mass adoption of electric vehicles. Governments need to support incentives for faster-charging battery technology, and encourage auto manufacturers to adopt ultrafast charging capability.

We firmly believe the future of the transport industry lies in the development of New Energy vehicles, specifically, battery-powered pure-electric vehicles. Electric buses represent the best long-term solution for public transport operators.

— Frank Thorpe, Managing Director at BYD UK

How can we optimise automotive supply chains for sustainability?

The replacement of incumbent materials in the automotive supply chain with more sustainable options faces many challenges. Automotive manufacture is a conservative industry that is often reluctant to adopt new materials due to long and costly qualification processes. In addition, the automotive industry is composed of complex (sometimes global) value chains in which each stakeholder (OEM, Tier 1s, raw material suppliers) have different investments, interests, and motivations for (or against) change, meaning that sustainability and monetary benefits may not be spread evenly across the value chain.

Hong Kong-headquartered independent consulting firm GXS Partners applies a number of different approaches aimed at bringing together increased business and sustainability benefits to support successful commercial strategies for UK and Chinese new energy companies. In one recent project, the goal was to identify strategies to increase the penetration of advanced polymers in automotive applications. While the main production capacity is in the UK, 80% of potential growth is in China. These polymers have many sustainability benefits over traditional products based on cross-linked polymers in both NEV and ICE vehicles.

To achieve this, GXS identified the many different specific OEM/Tier combinations for the heaviest parts in the car that could be replaced by advanced polymers, including deep dives into specific China EV ecosystems. It then developed an advocacy plan leveraging “value-in-use calculations”, thereby monetising through modelling the costs and benefits of switching to advanced materials, as well as documenting the competencies required to promote conversion to advanced polymers – particularly critical for China as the country is still in the early adoption and learning phase for some relevant technologies.

What green materials are needed for electric vehicles?

In the creation of electric vehicles, materials that are lightweight, resistant and do not interfere with any magnetic properties of the motor are essential. This was a key consideration for teams from the UK and China in the Formula Student international engineering design competition this year. Materials supplier Goodfellow supported the development of two different vehicle prototypes in the worldwide competition.

During the development process, one challenge tire company Goodyear faced was the grounding of cars parts due to the vehicles running with such a high voltage (600 V). Goodfellow reviewed different material options in order to come up with an alternative to using cables, and supplied around 3.5m2 of copper mesh to be used in the chassis monocoque of one of the vehicles. This material was used to put the whole car on the same potential, like a Faraday Cage, preventing the driver from conducting high voltage electricity.

How new fuel cells can power the transport of tomorrow

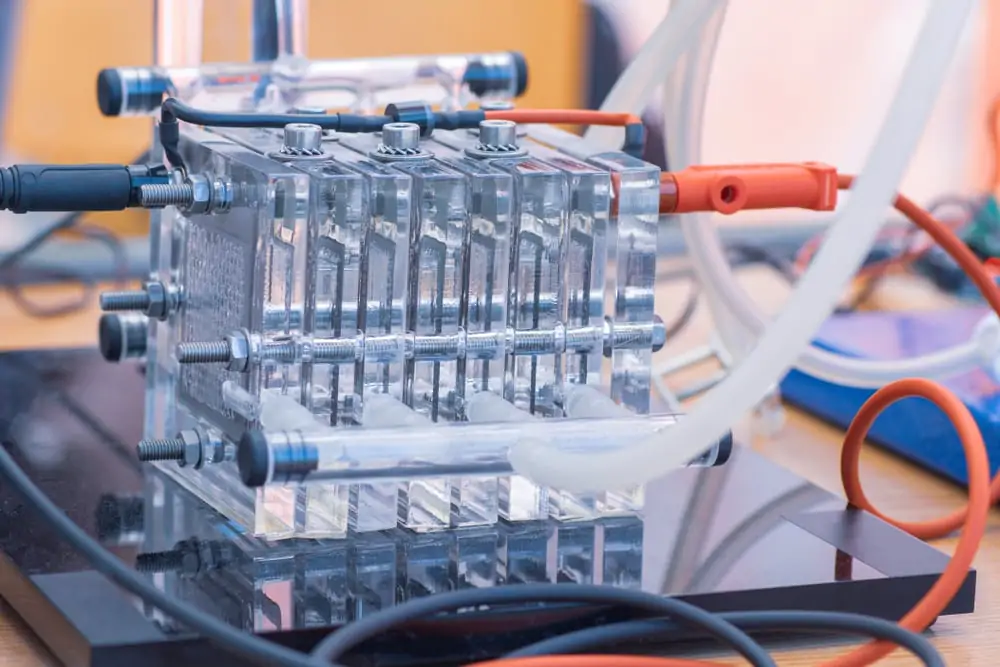

Hydrogen has the potential to significantly contribute to the fight to tackle the climate crisis by decarbonising industries that are difficult to electrify, such as heavy industry, heavy mobility, aviation and shipping. This is a critical step in helping societies meet their ambitious Net Zero targets. For example, fuel cells are an attractive solution as societies act to decarbonise emissions from transportation – one of the most significant contributors to greenhouse gas emissions globally. Fuel cells use clean or low carbon fuels, such as hydrogen, to generate power and produce no harmful emissions, with water as the only by-product. They have proved ideal in heavy-duty or high usage applications, such as trucks and buses, because of their longer range, low relative weight, and fast refuelling times compared to battery alternatives.

Through many years of collaborating with fuel cell suppliers in China, leading sustainable technology company Johnson Matthey’s fuel cell technology is already powering more than 700 fuel cell buses and commercial vehicles on China’s roads today. These have clocked up more than 6.5 million kilometres of zero emission travel – equivalent to 350 round trips from Johnson Matthey’s UK site in Swindon to the new facility in Shanghai. In 2021 1,000 vehicles will be built using our materials in China, increasing to 3,000 in 2022. Overall plant capacity is enough to power more than 10,000 buses and commercial vehicles, avoiding 125,000 tonnes of CO2 emissions from China’s roads every year.

How a UK-China partnership is bringing e-mobility to Britain

BYD Company Ltd is one of China’s largest privately-owned enterprises. Since 1995, the company has pioneered the development of rechargeable batteries and remains fully committed to the global programme of decarbonisation, successfully expanding its renewable energy solutions with operations in over 50 countries and regions.

After having entered the UK market in 2013, BYD UK has quickly established itself as number one in the electric bus industry, remaining at the forefront of the switch to eMobility in towns and cities right across the country. In 2015, BYD UK joined forces with Alexander Dennis Ltd. (ADL), one of the best-known names in British vehicle manufacturing. The partnership’s two base models include the BYD ADL Enviro200EV single-deck and BYD ADL Enviro400EV double-deck. The BYD ADL partnership has developed into a hugely successful collaboration.

In March 2021, ADL and BYD UK jointly announced that their electric vehicle partnership has taken an order for 22 BYD ADL Enviro200EV electric single deck buses from First Bus. The buses, which are part-funded by the Scottish Government, will operate as an official shuttle for COP26 delegates.

Today, the BYD ADL partnership has over 500 electric buses in service in the UK, clocking up over 25-million pure-electric miles and reducing CO2 emissions by 40,000-tonnes. A further 500 vehicles are on order for public transport operators right across the country.

BYD is also playing a key role in the UK’s innovative Bus2Grid Project, delivering its technological expertise for the switching-on of the world’s first high-power discharge facility at Go-Ahead London’s Northumberland Park bus depot. A fleet of 28 BYD ADL Enviro400EV double-deck electric buses are also being deployed for the project, with the vehicles providing bi-directional charging, capable of returning energy back to the power grid.

Along with its partners – SSE Enterprise, UK Power Networks and Leeds University – BYD has helped install innovative new ‘Vehicle-2- Grid’ (V2G) infrastructure and is the first company in the commercial vehicle sector to provide high-power discharge technology as a V2G capability for electric buses. Vehicles are recharged overnight when energy demand is low, and tariffs cheaper, with electricity fed back to the grid when demand is high, thus helping to balance the network and increase efficiency.